India’s industrial growth has to now span a localized paradigm, as envisioned by the Prime Minister of India Mr. Narendra Modi. This localization of economies is not an alien concept to India – indeed, the concept of such localization has always been conspicuous by its presence in folklore and public memory. Be it the sweets of Agra and Mathura, the silk of Kanchipuram, the muslin of Bengal or the shawl of Kashmir, such localization that harnessed a region’s natural resources and fused it with the local talent has always been commonplace. However, the nature of New India has to be glocal – global yet local, as it looks to regain its lost position in a new world. However, this has to be done on the back of manufacturing, a large chunk of which has to be based on the small scale sector of India.

The importance of small scale sector across the world has never gone unnoticed. Worldwide, a wide range of responses across different countries have come across to support the Micro, Small and Medium Enterprises (MSME) sector of their countries in this time of desperation. The IRS officers’ association in their Report Project FORCE noted the varying responses, listed out as follows:

- Shortening the working time, temporary layoff and sick leave

- Deferral of tax, social security payments, debt payments and rent and utility payments

- Extended or simplified the provision of loan guarantees, to enable commercial banks to expand lending to SMEs.

- Direct lending to SMEs through public institutions.

- Grants and subsidies to SMEs and other companies to bridge the drop in revenues.

- Countries are putting in place structural policies to help SMEs adopt new working methods and (digital) technologies and to find new markets and sales channels to continue operations under the prevailing containment measures.

- Enhance cash flow measures.

- Specific schemes to monitor the impact of the crisis on SMEs and enhance the governance of SME related policy responses

While the Indian government deliberates on the measures needed, so far the industry support has been partial and more regulatory than fiscal in nature. MSMEs however need greater attention for a whole host of reasons, which have been discussed subsequently. However, suffice to note that there is a need for a well thought out policy. However, a chance at a reset for the sector as a whole and manufacturing at large in India has arrived due to COVID-19 that is disrupting the global economic order in multifarious ways. MSMEs shall play an important role, provided the right steps are taken up.

MSMEs – the Backbone of India

MSME contribute 29% of India’s GDP and employ about 97% of the workforce across 7 crore entities spread all across India. The importance of the sector should be more than appreciated, as one would naturally expect. However, that is not to be – India continues to import high volumes of low-technology goods from other markets including China. The situation that has developed over the years has gained enormous proportions in recent times, highlighting the dysfunctionality in policy on the subject of the MSME sector in the policy making circles. Just to put thing in perspective, India increased its share in manufacturing value from 1.1% in 2000 to 2.0% in 2010, whereas China grew from 6.7% to 15.0% over the same period. Moreover, the importance of the MSME sector can also be gauged by the fact that India’s share in manufacturing exports was 28.2% in 2010, whereas the same for China stood at 60.2% in 2010.

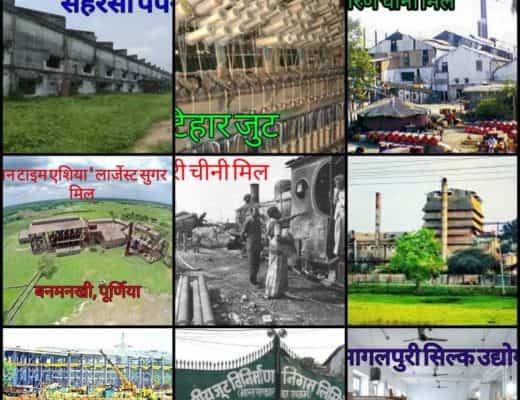

As per Anil Bhardwaj, Secretary General, FISME, factors such as cheaper land, regular electricity, cheap finance and good roads contribute in making Chinese SMEs gain 20 to 40% efficiency. This has resulted in expansion of the import portfolio from low value goods to high value goods as well. Things however have never been a smooth ride for the MSME sector of India, often subjected to step motherly treatment, pushed to the extreme by policies in India. For instance, India’s MSME sector bore the brunt when small manufacturers of LED shut shop as duty free parts from China flooded Indian markets. A lot of manufacturers shifted to assembling activities, as the price of raw material from China was higher than the selling price of finished displays in India.

Another industry similarly affected was the bicycle manufacturing ancillary industry. The import-export ratio of the industry has now reversed due to a 10 to 15% cost difference in parts imported from China such as hand levers, spokes, hub cones and chain wheels. Rising prices of raw material and shortage of labour have dented the industry that was once a driver of Punjab’s economy. What makes it worse is the South Asia Free Trade Agreement (SAFTA) that has been exploited by local manufacturing within neighboring countries like Sri Lanka and Bangladesh, who in turn have also become conduits to an extent to the cheap parts flooding Indian markets, squeezing out the local MSMEs.

The electronics component industry shares similar experiences, where the market suffered due to duty free imports of about 217 categories of electronic components post the FTA in 200. Certainly, there are steps being taken to revive the industry through cluster-based infrastructure and tax concessions. However, to achieve economies of scale and compete with the dragon is still work in progress. To put things in the clear, the India ASEAN FTA has led to the dilution of the quality of trade products. Trade balance for India has worsened in 13 out of 21 sectors, including value added sectors like chemicals and allied, plastics and rubber, minerals, leather, textiles, gems and jewellery, metals, vehicles, medical instruments and miscellaneous manufactured items . These sectors account for 75% of India’s exports to ASEAN.

Some Realism For the MSME Sector on Market Size and Currency Valuation

Policymakers despite their earnestness to set things right have been in recent times ignorant of the massive shift that has taken place in the industry outputs. Every time there is talk of the eocnomic growth, all that we seem to be discussing is the huge market size of India. If the huge market size of India was such an important thing, one would beg the question – why is the MSME sector unable to cater to this domestic market and benefit from it? Clearly, policymakers in the government continue to overestimate the ability of Indian market to absorb things. It remains a fact that some of our best industries were really earning from exports, be they big corporations or MSME sector driven sectors. Textiles, auto, ceramics, pharma – you name it, the export earning is big, with the domestic market literally being an also ran for the major players of the country. Export promotion schemes are criminal in the sense that they still continue to prefer supporting small industries instead of actually incentivizing growth through special credit schemes. A perverse situation thus is created – industries want to remain small and do not wish to think of local markets in true revenue terms, something that can be enabled by a massive expansion of capacities that could cater to the Indian market as well.

Another issue that seems to be repeatedly under-explored is the valuation of the currency. Several business analysts and market economists like Sajid Chenoy have regularly pointed out that India has really seen growth in the past two decades when two factors converged:

- Export oriented units, especially MSME sector boomed and got big orders

- The Indian Rupee’s real value came down, and was not artificially propped up, enabling cheap exports.

These thoughts really need to be considered by the government as a hard political choice – letting a free-fall of the Indian rupee’s value happen. While the Reserve Bank of India has rarely interfered in the currency exchange valuation processes, a bold step can be taken that pegs the Indian rupee to a narrow basket of currencies, and letting a limited free fall of the Indian rupee’s value against those currencies. The political fallout of such a decision can be difficult to gauge; it remains to be seen whether the government would be willing to expend some of the political capital it has built up in the past six years to take this hard step that can help turn around the fortunes for several export oriented units along with other steps. Currency value control has been critical for the powering of the economies across East Asia and ASEAN, and the sooner this is realized, the sooner a bold step could perhaps be enabled.

Raw Materials and Low Production Cost – A Path of Rectification Necessitated

Another issue, raw materials, are a true challenge that confronts the MSME sector, both for its supply chain as well as its very existence in the ancillary space. We had mentioned earlier the example of the bicycle industry and the downfall of the ancillaries. That industry is not in isolation – multiple sectors across India suffer the same fate. An industry like chemicals gives a sobering assessment about the entire world, not just India – China produces almost fifty per cent of the most commonly demanded chemicals for the world. Even in industries like pharmaceuticals, China captured the Active Pharmaceutical Ingredient (API) space -we don’t even necessarily make Vitamin C in India, a task that can be easily done by small scale industries without the need of sophisticated technology or raw material inputs. It is not that these capacities have never been present in India; however, in recent times there has evolved a situation where Indian companies are unable to achieve scale, pulled down by past policy mistakes and present policy apathy. This inability of the Indian MSME sector to undertake low end manufacturing of raw materials and basic goods at low enough costs is something that can harm India’s ability to attract investors. Big companies don’t make buttons and zips, but small ones. Nearly every button sewn, every zipper.attached to a pair of denims in India today is Chinese, to put things in perspective.

This is where a refocus on the MSME sector is critical in India. It is not just about becoming mom and pop stores driven economy; rather, there is a need to generate the establishment and propagate the expanding networks of more MSMEs who actually manufacture at low costs with quality. This is an essential to be able to create hubs that support manufacturing on a large scale while also reducing dependencies on other countries. It is worth considering that 30 per cent of all automotive components used in India’s famed automobile manufacturing industry today come from China – an opportunity awaits, that upon revival can go beyond the domestic market as well, creating jobs as well as become global in its reach and outlook. The question to examine is whether we are ready for this.

A Window of Opportunity for the MSME Sector

In a post COVID-19 world, it is expected that India will be looked as an option by domestic and foreign incorporations. With very little surplus making its way from China, India’s handicrafts, carpets, furniture and other low technology segments stand to gain. There will be inhibitions related to capacity and quality of products, and therefore, Indian manufacturers need to plan tactfully. Competition from Bangladesh, Vietnam and Philippines can be overcome if Indian manufacturers deliver on timelines and product quality. Apart from technology-driven products, India also has a clear edge over others in handmade products across sectors.

News came in recently of the government going all out to woo industries willing to move out of China. While the effort of the Indian government is certainly appreciable and timely, there are a few things that policy makers really need to ponder on the subject of the MSME sector’s pitiful status in the past few years. Taking a step back just to think of back is also needed to understand just where we stand and what we need, especially with respect to the potential wave of industrial expansion that we are aiming for.

Situations of crisis demand pragmatism, and it is time that the government also becomes pragmatic about the MSME sector. The government machinery’s understanding of MSME really needs to change. Obsession with the small scale of the establishment makes no sense, and such definitions as ₹5 crores or less turnover or 100 employees or less really need to be revised. The government should realize that manufacturing is a different ball game – not everyone is making papad and churan, and ironically even these units have higher turnovers than that. Manufacturing based MSMEs will certainly have far bigger turnovers, and so all kinds of benefits that have to be given really need to be given to all kinds of MSMEs as well. These incentives have to however be linked to growth, quality and competitiveness, and not to sustain small sizes.

Steps that Help Recalibrate Our Relationship With the MSME Sector

That the MSME sector has been languishing for a while now is no hidden secret. Several issues have compounded the problem, pushing entire sectors towards closure. While the government talks of a ₹1 trillion package for the MSME sector, a package is insufficient in addressing systemic issues that have been plaguing the industry. A reset is definitely needed for the space, with a breather being granted to them in many ways. COVID-19 has only gone on to hurt the MSMEs in big ways; however, constant harassment on other fronts have been the underlying factor that caused the situation to reach where it stands today. The sector is in need of support not just financially but also from policy perspectives, and it will certainly be in the government’s interest if it is truly keen about pushing for manufacturing in India to create jobs now to ensure this sector doesn’t collapse. There are a host of issues that the government needs to address swiftly in this regard – these problems have been causing pain, and should not have merited a COVID-19 response to facilitate them. However, as the adage goes – better late than never.

Release GST Input credit immediately. Input credit often serves as working capital for several MSMEs that often have thin margins, and so holding it back is as good as financially impairing them, especially within a financial market that views them with suspicion. Another important step that will help both now and in the long term is to amend the GST rules such that tax deduction is collected after the entity’s payment comes, not at invoicing stage. This is exactly the issue when the advances are taken by the MSME to use as working capital for the job order they receive. Taxing that without adequate financial support for the sector is criminal in every sense.

There are a large number of already extant funds that cater to various kinds of MSME sectors. It would be far better to merge these funds and set up a super MSME fund. The scale thus achieved will be extremely helpful in creating greater leverage and also providing cheaper credit. All these funds and schemes can be combined into the extant MUDRA scheme and the cap of less than ₹1 crore be raised to at least ₹3-5 crore in turn for working capital loans. In the short run, this fund should also give an overdraft of about 2 months’ employee salary to the MSMEs without any collateral – with a low rate of default, the sector is more than worthy of this basic minimum support. Moreover, the MSME fund should also work with banks and NBFCs to provide first loss coverage in the post-COVID scenario – risk being a major factor that NBFCs and banks cite, the fund can provide both insurance and risk guarantee for the banks and NBFCs to kickstart the MSME sector again, which if the plan goes would have a ravenous appetite for credit.

Taxation is another vexatious issue that has emerged. Of course, no tax holidays are possible, and the government seems less than keen to give up on tax collections that form the lion’s share of its revenue in the financial year. In such a scenario, the minimum that can be done is to completely waive off interest to be collected on deferred tax payments. Reducing from 12 percent to 9 percent does not make sense at all, considering the lack of any earning whatsoever within the MSME space as of now alongwith the pending dues like salaries that the government expects the sector to pay out.

This brings us to another important point – even though the Centre has been working hard to clarify the issue of salary mandates, states will certainly not backtrack from this for obvious political capital reasons. While the urge to sort this out immediately is more than evident, a middle path can be found. Let the MSMEs instead bear the food and rental expenses of their employees and their families. This is the critical factor that can help everyone in the purpose. Additionally, the fixed term contract needs to be sorted out immediately by the states, as the opportunity for a reform of this kind will not come again, being a win-win situation for everyone.

Loan EMIs have been deferred by the RBI; however, it is ironic that the additional interest continues to accrue, thus defeating the purpose of the deferment, which was the minimum expected for now. This is grossly unfair as the companies in the MSME space are trying to survive, forget a recovery post COVID, and can be detrimental for the sector in the mid term. Instead, the government should consider to compensate the banks to cover this through the use of such options such as debt bonds so that the industry can be granted an interest holiday. With the bonds issued, the MSME sector can also have breathing space provided that the interest holiday does not translate into any interest on interest kind of perverse scenario, as is often the case.

ESIC has been the tool used for insuring labour working with the MSME sector. Along with it, the sector has also been paying out Provident Fund contributions. While the coverage on PF has been granted, there is a need to work on the ESIC premiums, especially with the COVID problem not going anywhere any time soon. ESIC coverage against standard premiums must be raised by the government. If needed, a raised premium with a portion of that premium being paid for by the state or central governments across different establishments already issuing it can be opted for. Also, the ESIC and Ayushman Bharat coverages should work together to ensure that the maximization of the benefits including coverages can in fact be achieved by simple scale. A single health insurance coverage therefore would benefit the labourers in a big way. Further, the PM Jeevan Bima Yojana and Suraksha Yojana insurance schemes, that provide ₹2 lakh and ₹1 lakh under different conditions are immediate schemes that can be utilized – the cover should be increased, and the extra premium necessary for it should be paid for by the government.

In the post-COVID scenario, the MSME clusters face a particular challenge of managing sanitary set up. However, the cost needs to be pooled for clusters in particular to minimize the challenges at the establishments. State governments can consider setting up sanitization systems that can be commonly utilized by all. Common sanitization tunnels at the various entry points of every industry cluster, just like those set up in mandis and agricultural markets is feasible and extremely helpful, and can help to reduce the burden brought about by the new kinds of hygiene sanitary costs for MSMEs. Further, governments and NGOs can be made to work with labour contractor agencies to ensure that practices related to sanitation, health and hygiene at their end are the new norm; it just cannot be the duty of the MSME alone to ensure these measures.

Finally, the raw material supply has to be ensured for MSMEs. Currently, these chains stand completely disrupted; ways have to be found to develop local supplies alongside restoring the presently disrupted ones. With the utter confusion in truck movement creeping up repeatedly, MSMEs will suffer enormous damages arising from this continued challenge. Working with states to ensure that this does not happen, just as the GST managed to do this. The same has to be worked out for the employees as well. Having provisions on travel of employees to mere cycles or on foot is laughable – what if the MSME wants to use buses to transport? In such a scenario, there is an urgent need to address transport issues for employees. The need for movement passes will come up, and to enable the passes to be issues, Jan Seva Kendras can be utilized swiftly.

Make in India has to start again. But for that to happen the MSME sector really needs to be treated better. Government babus need to stop treating MSME as an afterthought. Viet Nam and Bangladesh have become big precisely because of their local MSMEs. We could too, but conditions apply.